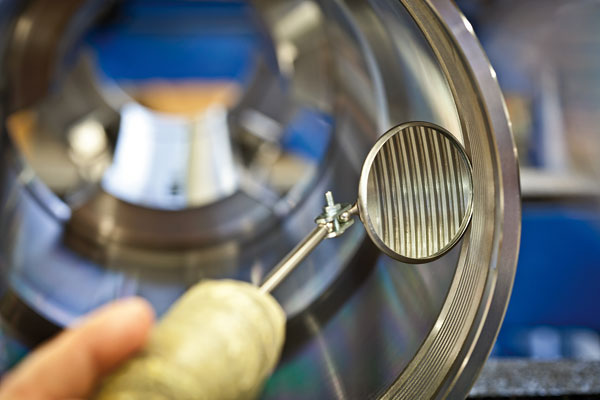

Visual testing is the location and evaluation of surface-related quality features, such as deviations in shape, discontinuities and surface properties of a product, with the human eye or using optical aids (e.g., magnifying glass, microscope, endoscope, etc.).

Visual testing is the NDT process we use during a comprehensive inspection before all other destructive and non-destructive testing. The knowledge gained here is an important prerequisite for all following testing processes.

From its inception, Klaus Gross GmbH & Co. KG has been in the business of non-destructive material testing, which allows us to look back over a treasure-trove of 30 years of experience. This experience, combined with a high degree of flexibility and highly motivated staff, has characterised us from the beginning.

We can carry out any process we offer either at our premises or at the client's location. This applies to HT, PT, MT, RT, UT or VT tests; on request, we can provide a complete evaluation and documentation directly on the spot. We can ensure this as we use only personnel qualified at Level 2 in our operation. For test supervision, there is also a Level 3 tester in house.

For many years, our range of activities has included the inspection of drilling rods. In this respect, we have trained some of our employees in the NS2™ standard, which ensures the highest level of quality.

See the sub-menu points for a quick overview of the testing processes we carry out. Our skilled personnel are available for questions at any time.